There are many stereotypes that we see in Hollywood. One of them includes tomato juice and… airplanes. There were many speculations why people are enjoying this particular beverage onboard an airplane. One of them says that your taste buds aren’t really working as they should during a flight. The reason? Same as your dry eyes after a long haul flight – pressurization.

The typical jet airliner is cruising at very high altitude, somewhere between the troposphere and the stratosphere. The density of the air up there can kill in less than a minute. To make things easier to understand we won’t mention the freezing cold just yet.

A human body is the most comfortable in altitudes no higher than 3 kilometers ASL or 10 000 feet. Given the usual cruising altitude of 11 km, airplane uses the system that keeps the air pressure inside at the comfortable, safe levels. While flying on your long-awaited vacation, your body experiences a feeling of being in the moderately high mountains. It’s not that bad. But why we get the dry eyes and less taste up in the air?

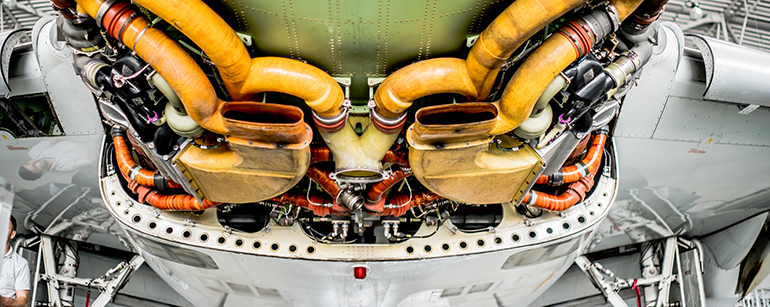

Even the regional jets are capable of taking around 100 passengers. That many people can’t breathe the same air that was “taken” from the ground. The main source of air supply is called PACK. This acronym stands for Pressurization and Air Conditioning Kit. To understand how it operates you need to know a bit about the jet engines.

In order to create thrust, mainly produced by the big fan in front of the engine, jets are taking millions of liters of air from the atmosphere. Most of it is just bypassed to create thrust. However, some of it is used to burn with the fuel. That part of the air is driven to the many sets of stators and compressors, which elevates the pressure and temperature. Before it goes to the combustion chamber, hot and highly compressed air is taken by so-called bleeds. The bleed air is then further cooled to the sufficient level and pumped into the fuselage.

The bleed air, along with PACK is one of the most complex systems in the aircraft. It requires regular checks and possible repairs. At LINETECH we always make sure that every component of PACK and bleed air is operational and well maintained.

At the very high altitudes, air is thin and freezing cold, varying between -40 and -70 degrees. There’s virtually no humidity. That dry air can’t be in any way humidified. The reason? Humidity can cause corrosion that weakens the airplane skin. It could lead to catastrophic, explosive decompression. Luckily, many of the new airliners use composite materials. The composite doesn’t corrode, so the air can be artificially humified. That gets rid of your dry eyes, but keeps your body at the altitudes that will make love tomato juice – even if you hate it on the ground.

Although composites are one of the most advanced materials on Earth, they also require regular checks and repairs. LINETECH is proudly one of the leaders and founders of Polish Composite Cluster. We work hard to maintain them. We are sure that our experience and suggestions can be useful to produce even better materials in the future. Maybe one day we will help to design the material that strong, that you wouldn’t feel any of the pressurization side-effects, starting from the most unusual – the love for salty tomato juice

Leave a reply